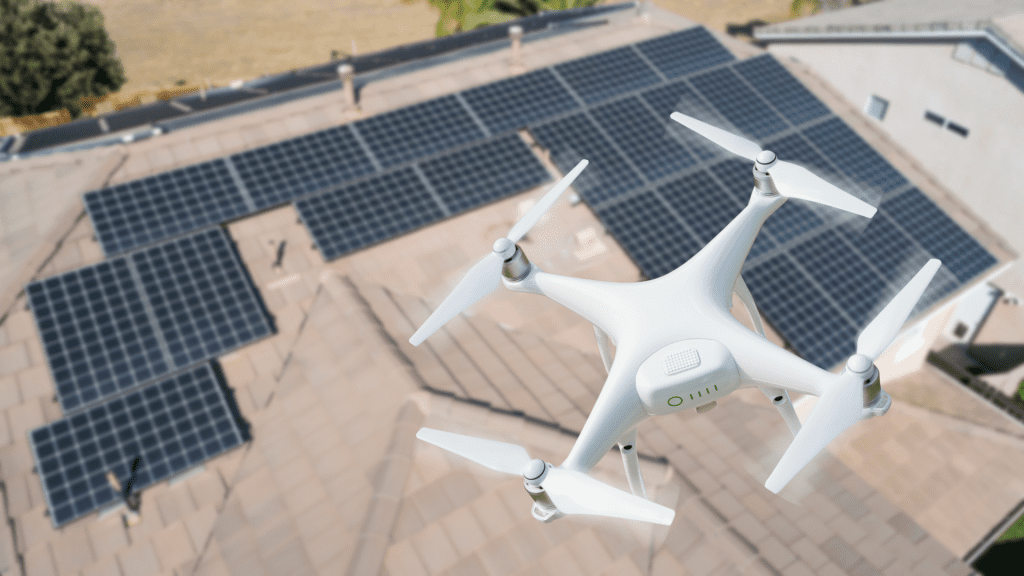

In the digital world, many people use drone data solutions to reduce their time and money which can be spent on manual inspections. The drone software can be more efficient on the job site. Using drones can increase worker safety and improve documents such as asset inspection.

Dronedeploy is used for inspection from the ground level, determining the document problems from the office, and cooperating with the team members to solve those issues.

When you already have a drone solution on your site. When you are trying to start a drone inspection, I will provide some ebooks to learn about drone solutions.

The ebooks that can examine for you:

• What is a drone data solution?

• Benefits of Drone Data for Inspections

• Usage of Drone Inspection Across Industries

• How to get started with DroneDeploy

Drone Data Solution

The drone can take huge amounts of data through photos, videos, panoramas, and even multispectral and thermal imagery. When all information is gathered it can make hundreds to thousands of files. The crucial companies use a software solution that can learn this information and make it digestible for your operational fields, R&D team, and clients.

This was the only company that interprets all drone data by helping the companies capture, analyze, and take action.

Benefits of Drone Data for Inspections

Drone inspections can stand on the zenith of efficiency and safety in industries. Today the new technology emissaries can conduct assessments at a secure altitude and perform tasks with an unparalleled level of detail. The distribution of high-resolution or 4k video data captures, sources from drones during the inspection, provide the meticulous examination, ensuring all the facts of the structure or area can be carefully scrutinized. The depth analysis can be virtually unattainable with traditional inspection methods. The drone can take less time for inspection than traditional inspection.

Some additional Benefits of Drone inspection

Operational Speed of Drone:

The drones can capacity to survey and record all the details data over large areas transforming an inspection routine that a traditional survey can consume hours into a streamlined process taking merely 5-20 minutes.

Customization and Versatility of the Drone:

Drones can be invented the engineered to various inspection requirements, according to an array of sizes and tools at the operator’s disposal. It can prove invaluable data for extensive data collection across various landscape inspections from a complex urban infrastructure to sprawling agricultural expanses.

The UAV inspection for environmental and maintenance implications.

Proactive Maintenance: proactive maintenance can accelerate the identified risk factors, drones enable predictive maintenance protocols, effectively preventing destructive problems before they calculate.

Environmental Conservation: The drone employed can be inspected to serve the environment by shrinking the carbon footprint and minimizing the intensive elements like chemical usage and noise pollution, all while enhancing wildlife and habitat conservation efforts.

The industrial drone inspection sector can grow perpetually, with UAV technology and drone services shaping the future of safety compliance, operational efficiency, and asset management. As regulations adapt to these innovative tools, maintenance inspections are undertaken through drone technology.

Usage of Drone Inspection Across Industries

Drone inspection can grow rapidly which becomes the winged workforce across the spectrum of industries, the more efficient, and cost-effective paradigm for an inspection job. In oil and gas, drones have become invaluable for getting detailed images and videos, that can ensure the inspections that can carried out with unparalleled safety and efficiency. They soar above complex infrastructures, capturing important data from eliminating the risks associated with sending personnel into explosive environments. Here are some points to know how drone inspection across industries.

Nuclear Power Plants:

The two things that are most important for every industry and company and the two things are safety and security measures. It is the priority for every industry. You must use advanced sensors and imaging capabilities drones can assist research organizations can executing precise aerial inspections without human exposure to radiation and other dangers.

Power Lines and Solar Farms:

The deployment of drones which can be qualified with thermal cameras and lidar sensors. It not only finds defects and abnormalities but can also operate quickly to identify areas needed for maintenance. This UAV technology can provide essential data that can significantly reduce the risks and eschew labor-intensive manual techniques.

Oil and Gas:

In the oil and gas industries, the drone inspection service has become a crucial tool to initialize the infrastructure integrity and operational efficiency. In the industries, this is a golden opportunity to get a more cost-effective alternative to traditional methods. The drone can inspect meticulously in the vast tank farms for leaks and corrosion and eliminate the personal need to navigate dangerous surroundings. The drone has specialized sensors that can monitor the pipelines for potential damage or leaks. Drones can cover long distances in a single flight as compared to the ground-level method.

Drone capabilities are not only for worker safety. It also leads to significant cost savings for decreasing downtime and personnel requirements. Drones can capture all the data and provide detailed comprehensive insights, enabling proactive maintenance and informed decision making.

Wind Farms:

Drone inspection is integral to maintaining the operational efficiency of wind farms. Aerial platforms are occupied with sophisticated imaging sensors that can detect problems within electrical and control systems while monitoring the production capacity.

Drone Inspection During The Construction Process

Building & Roof Inspections:

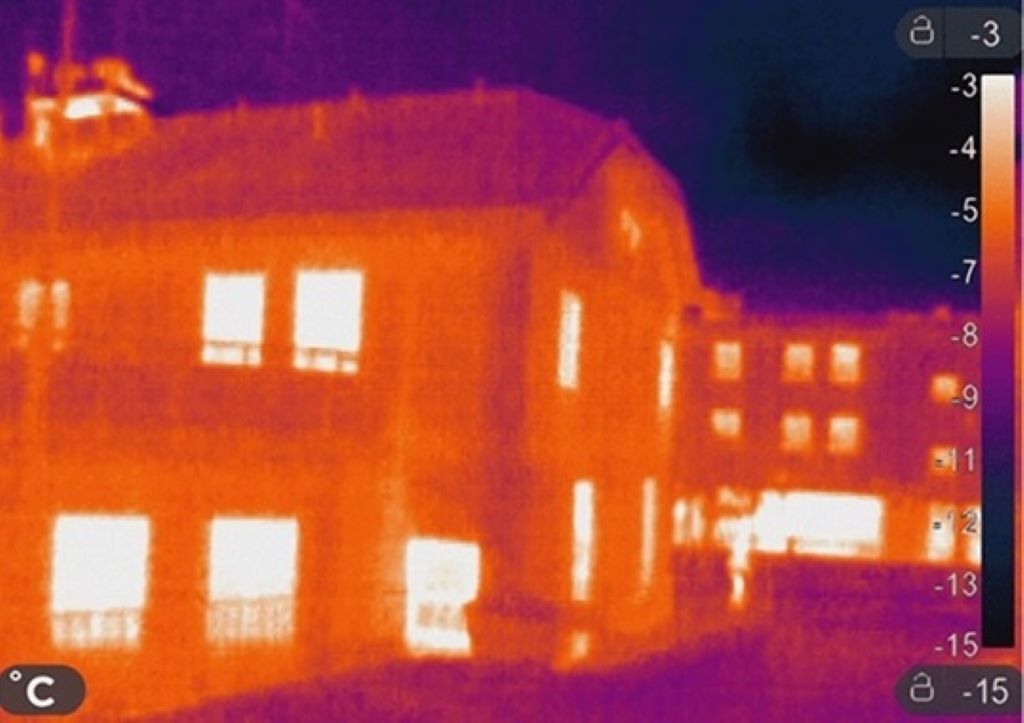

With the help of thermal images agile UAV detection insulation problems or water ingress can ensure the assessment of building integrity without compromising safety.

Cell Tower Inspections:

The latest drones can support 4k video recording capabilities. The high-resolution footage enables a meticulous review of the state structure to promote and maintain actions to avoid direct risks to human inspections.

Providing bird’ eye view for operational landscapes

- In agriculture, drones can monitor crop health to improve crop yields and save the time of farmers by rapidly covering extensive farmland areas and providing actionable data.

- In chemical plants, the UAV inspection can decrease exposure to harmful materials, decrease operational costs, and lower the chance of liability concerns, hence revolutionizing traditional safety practices.

- In the infrastructure and utilities, drones have fast data collection, mainly in potentially dangerous places making tower and bridge inspections not only safer but also more economical.

Drone technology can be underscored with a transformative impact on modern industry practices. Drone inspection is the pivotal tool that can be committed to safety compliance, efficient data collection, and evolving drone regulations. A drone can capture the data and restore it to the storage devices which can make it show impressive and attractive footage.

Thermal imaging with drone

Thermal imaging is used to help save lives in search and rescue operations by allocating the missing people or hikers, hunters, skiers, and victims lost outdoors. Drone can fly overhead during the day or night searching for heating signals indicating possible survivors using an infrared camera.

Drone technology has powerful tools for public safety. Unmanned aircraft systems have to be used to help save lives in response to many situations. It includes search and rescue missions, law enforcement crime scenes, and response to natural disasters like fires or other dangerous methods

This is one of the most impactful developments in drones for the adoption of thermal imaging sensors.

Drone Technologies

Drone technologies is an aerial vehicle that can receive remote commands from the drone pilot or depends on software for the use of autonomous flight. Many drone technologies can display their features like cameras for collecting visual data and propellers for stabilizing their flight patterns.

Drone Technologies

Radar location and homecoming

Today drone technologies can operate by the GNSS and non-satellite mode is the combination of Global Navigational Satellite Systems (GNSS). This can provide a navigation system that brings 3D map creation, navigation, and search-and-rescue (SAR) tasks while flying the drone. The drone technologies provide information about the current location, return home using the button for any reason, reach the set low battery level, and record the starting point for the “Return to Home” feature in case of loss of communication between the drone and the remote control, and can return to the starting position without any problems.

Technology for detecting obstacles and preventing collisions

Drones are occupied with collision avoidance systems for safety purposes. These systems consist that they can’t scan the environment but detect obstacles. Data from the vision sensor, ultrasonic, infrared, LiDAR, time-of-flight (ToF), and monocular vision sensors transform images into 3D maps, allowing the flight controller to detect and avoid the object.

Patterns of movement for drones

Roll is the Z-axis on the nose and tail of the aircraft, i.e., longitudinal. It means it rotates around the axis; the wings move up and down

Flight controllers, the IMU, and gyro stabilization

The gyroscope immediately responds to varying forces coming into the drone by providing the necessary navigation information to the central flight controller. The inertial measurement unit (IMU) detects the current acceleration rate using the accelerometer and the gyroscope to see changes in rolling characteristics such as pitch, roll, and yaw.

Propeller design and orientation for drone engines

Motors and propellers are the technology that lifts the drone, allowing it to fly or hover. On a quadcopter, the motors and propellers work in pairs, with two motors/propellers rotating clockwise and two motors/propellers rotating counterclockwise.

Drone technology with GPS ready-to-fly and no-fly zones

According to the compass calibration, when the drone starts to work, the drone searches for the position of GPS satellites; when more than six satellites are detected, the drone becomes “ready to fly.”

Making 3D models and maps

The drone visualization’s hyperspectral, multispectral, LiDAR, and thermal sensors are created by 3D digital surface models (DSM) of buildings, earth, and landscape and the land’s digital height maps (DEM). It has become very easy to make evaluations and plans about agricultural products, flowers, fauna, shrubs, and trees.