Maximize savings with Infrared Drone Solar Inspections! Learn how this advanced technology boosts efficiency and cuts maintenance costs.

Solar farms among other sectors use solar panels to generate energy sustainably.

This approach offers excellent energy production but necessitates aerial solar inspection to reduce costs of maintenance and ensure that solar panels are not faulty and are producing as they should.

Manual inspections of solar panels, especially in high-risk areas, can be risky and time-consuming.

Instead of wasting time and energy by inspecting each solar cell in a solar farm individually, deploying drones armed with drone technology fast-tracks the process in terms of safety, time, and effort.

Drones are used in solar businesses for assessing damage or wear on panels. Solar inspections using infrared drones can prevent unnecessary expenditure on fixing panel malfunctions that will be too expensive if unattended.

These devices have practical uses almost without limits; hence, they are changing the way modern firms operate. Drones are increasingly being used by companies in the solar industry due to the many benefits they provide.

Infrared Drone Solar Inspections Explained

However, it is important to first understand the basics of infrared technology before discussing its advantages. Infrared radiation is electromagnetic radiation that has longer wavelengths than visible light.

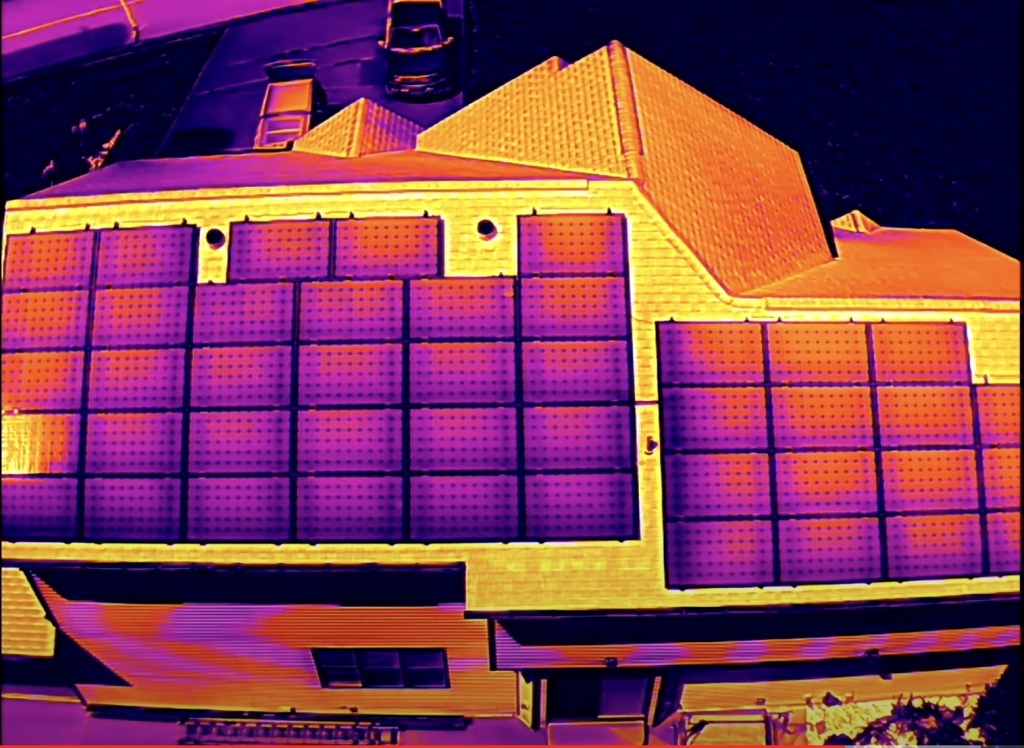

In the context of solar inspections, infrared cameras can record heat signatures and thus identify hot spots, malfunctioning cells, or any other faults that might impair the operation of PV modules.

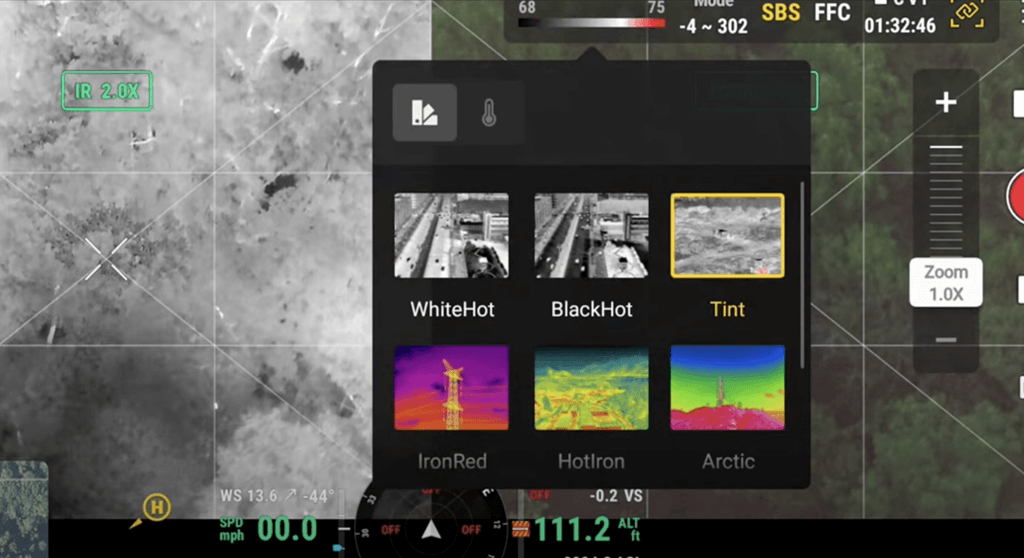

Using high-power optic cameras, solar panel drone inspection can inspect your solar assets by taking optical pictures as well as EO/IR images which give clear images for reliable evaluation

Drones make it easier to examine solar panels. They fly on a predetermined flight route at certain speeds and altitudes. They may use high-quality cameras to cover your whole solar panel farm and collect data.

Then you review the reel to keep track of how well the system has been maintained as well as its quality, with a view of some areas that could be improved for better upkeep and efficiency.

With shorter flight times it is faster to collect data, speeding up assessments, maintenance, and upgrades and letting you handle more projects while lowering costs of operations and improving overall performance in solar farms.

Unveiling The Cost-Efficiency Of Infrared Drone Solar Inspections

Solar energy is a shining example of sustainability replacing our energy sources as we have known them. Yet continually enhancing its effectiveness remains necessary.

Enter Infrared Drone Solar Inspections: not only does it improve performance but saves money too

With the help of infrared technology, unprecedented accuracy can be achieved. It is this principle that applies to the detection of inefficiencies in solar panels.

From faulty panels to hidden wiring problems, infrared scanning leaves no room for error. These are some reasons why drone inspections for solar installations can save money.

Early Detection, Swift Correction

Infrared technology allows drones to detect issues that may not be visible during visual inspections.

The earlier these hotspots, defective cells, or other defects are diagnosed, the less expensive it becomes to repair them. The idea here is that there should be a proactive approach to maintenance to ensure long-term cost savings.

Hotspots or areas with higher temperatures can be indicative of various difficulties within solar panels. They may include malfunctioning cells, poor connections, or low overall output capacity of the panel.

These hotspots are almost impossible to identify through visual inspection alone under usual circumstances. Nevertheless, drones using infrared technology can find them quickly and ensure timely intervention.

Defective cells in a solar panel could have severe implications on its performance but they cannot always be seen visibly.

Infrared drone inspections enable the detection of these minor deviations by recognizing the temperature differences, defined by defective cells. From here on, this issue can be contained in a repairable state before it affects other cells.

Infrared drone inspections are driven by the need to reduce long-term costs. Addressing problems in their infancy, therefore requires maintenance teams to be swift and effective.

Doing this will stop issues from developing into bigger problems that would have caused greater destruction and increased repair or replacement costs if left unattended to.

As a result, the expenses of major repairs are minimized while maximizing the cost-effectiveness of a solar panel maintenance approach.

By so doing they are not only saving money in the immediate term but also protecting long-term investments in solar energy.

Enhanced Safety Measures

The use of drones for solar inspections also enhances safety measures apart from saving costs, unlike human inspection methods.

Inspections carried out manually usually require technicians to climb over roofs or operate machines at heights which could be risky. This way, drones help minimize risks associated with such activities hence promoting safe working atmospheres.

The space under the panels is too narrow for crawling during standard rooftop solar field thermographic inspections that can only be obtained by taking photos straight from the front.

Alternatively, specialists go up to the top and walk around the periphery at an angle so that they can scan rows of photovoltaic modules and find it more difficult to detect irregularities.

This data has less certainty due to reflection. Reflections are minimized when a drone flies over a roof and next to each solar panel making the drone capable of acquiring more accurate images.

One of the primary safety benefits of using drones lies in their ability to conduct inspections remotely.

Drone operators can control them from a distance, thereby enabling them not to get near unsafe situations. This remote control enhances not only safety but also gives an encompassing perspective on what a complete solar installation looks like.

The use of drones in solar checks prioritizes technician welfare. Instead of engaging in physically demanding and risky activities, workers can focus on operating drones and analyzing the data they collect.

This shift in roles not only minimizes the chances of accidents but also contributes to a more positive and sustainable work environment.

Direct Correlation: Optimal Energy Output And Cost Savings

The solar energy domain is a space where every watt counts. Each panel should operate at its optimal capacity hence the need for infrared inspections.

This means that by identifying and fixing the underperforming panels, the total energy output is maximized resulting in significant cost savings.

Infrared inspections are proactive as opposed to other methods of maintaining solar energy systems.

Rather than waiting for visible signs of wear and tear like reduced energy output or physical damage, infrared technology helps technicians detect minute variations early enough.

This approach ensures that maintenance is done on these issues before they become big problems leading to consistent energy production.

Any solar power system ultimately aims at efficiently capturing sunlight and converting it into electricity.

To achieve this, infrared inspections identify and resolve challenges that undermine the ability of individual panels to harvest energy.

By ensuring each panel operates optimally, the overall energy output of the entire solar array is maximized.

There cannot be more emphasis placed on how optimal energy production influences cost savings. When all panels are functioning optimally, it leads to maximizing the return on investment for an entire installation.

There can never be enough emphasis on the link between the optimum energy output and savings. The overall solar installation returns more if every panel operates at its peak.

Infrared inspection costs are nothing compared to the long-term benefits of higher energy production and fewer repairs caused by early treatment of problems.

Efficient Data Collection For Comprehensive Maintenance

Nobody else performs any kind of solar inspection as quickly or comprehensively as a thermal drone does. An infrared drone with a thermal camera provides more information in less time than conventional methods for inspecting huge areas of solar farms.

Moreover, this allows data collection to be less labor-intensive while at the same time ensuring that inspections take place more frequently and promptly, thereby enhancing overall maintenance strategies.

Solar inspections through infrared drones gather more data faster than human procedures. You can use thermal data to see whether your solar system is operating normally.

You could also process and analyze this information fast to know why the output is being lost, if it is; for example, faults, hotspots, incorrect installations, etc.

The temperature differences among these panels make this data very useful in establishing whether or not the solar system is functioning correctly. You can tell something is not right when there are temperature variations, which cannot be detected by visual inspection only.

This will help identify misplacement errors and correct them immediately at all stages of the entire installation through the infrared inspection data.

The point is to identify and correct such mistakes, whether they involve misalignments, poor connection or any other problem related to installation for maximum system operation.

Why Choose Drone Upload Media Services For Infrared Drone Solar Inspections?

Businesses, organizations, and individuals employ our services for aerial photography and video use cases that include Marketing and advertisement, Real estate, Construction, Agriculture, Industries, and Emergency/Rescue among others.

We strive to offer our clients excellent aerial media production services. Our skillful pilots as well as photographers who are CASA certified have been in this field for years. We have state-of-the-art equipment to guarantee the best possible results for our customers.

How Can Drone Upload Media Service Help In Infrared Drone Solar Inspections?

In Sydney, we offer professional video production as well as photography services. We create video and photography that drives brand impact. Whatever you imagine we can do it. There are several reasons why this approach is useful:

Remote Inspection

Using infrared technology, remote inspection of solar panels is facilitated by drone upload media services. Thus, the inspections can be done without necessarily visiting the place hence saving a lot of time and money.

High-resolution Imaging

With high-resolution imaging, drones that are fitted with infrared cameras assist in the detailed analysis of solar panels. Hence, it identifies problems such as hotspots or faulty cells and other issues that cannot be seen by the human eye.

Time And Cost Efficiency

Traditional methods for inspecting solar panels often involve physical labor and require significant amounts of time. Drones are capable of covering large areas within a short span thus reducing the amount of time needed to carry out inspections. This improves efficiencies that can lead to decreased costs for corporations and operators of solar farms.

FAQs On Infrared Drone Solar Inspections

Are Infrared Drone Inspections Cost-Effective?

Yes, infrared drone inspections are typically efficient over vast territories that help them spot issues early potentially avoiding costly repairs.

How Frequently Should Solar Inspections Occur?

Solar panel checks have to be performed at least once a year as standard practice. Nevertheless, this may not always be the case depending on factors like when was the system installed and where it is located amongst others.

Can Infrared Drone Inspections Detect Minor Issues?

Yes, thermal images generated by infrared drone inspections can capture temperature variations indicating minor problems enabling their early discovery and treatment.

Do Infrared Drone Inspections Cover Large Solar Farms?

Yes, infrared drone inspections are well-suited for covering large solar farms, providing a comprehensive and efficient way to survey extensive areas and identify potential issues across the entire installation.

Are Infrared Drones Environmentally Friendly?

Yes, infrared drones are relatively environmentally friendly compared to traditional inspection methods. They can reduce the need for manual labor, minimize disturbance to surroundings, and operate with lower environmental impact.